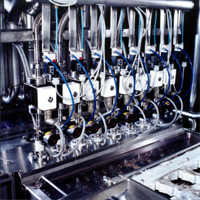

Dosing Meters for Filling Systems

Bopp & Reuther modular dosing meters for filling systems are used in packaging machines and facilities worldwide. Here at Metron, we support the stateside food and beverage industry, as well as many pharmacy and chemical producers.

Contact us for new and/or replacement meters, parts, and equipment.

Magnetic Inductive (MID)

Dosing Flow Meter

Dosing Meters – Advantages of Magnetic (MID) Meter vs. Piston Filler

- No product separation

- High filling speed

- Simple change of the filling quantity

- Minimal operating and maintenance costs

Dosing Meters – Applications

- Yogurt, milk, mayonaise, dressings, soups, edible oils

- Juices, water, beer, wine, brandy

- Champoo and soaps

- Cleaners, acids and alkalis, mineral and synthetic oils, etc.

Contact Us (For more information or a quote)